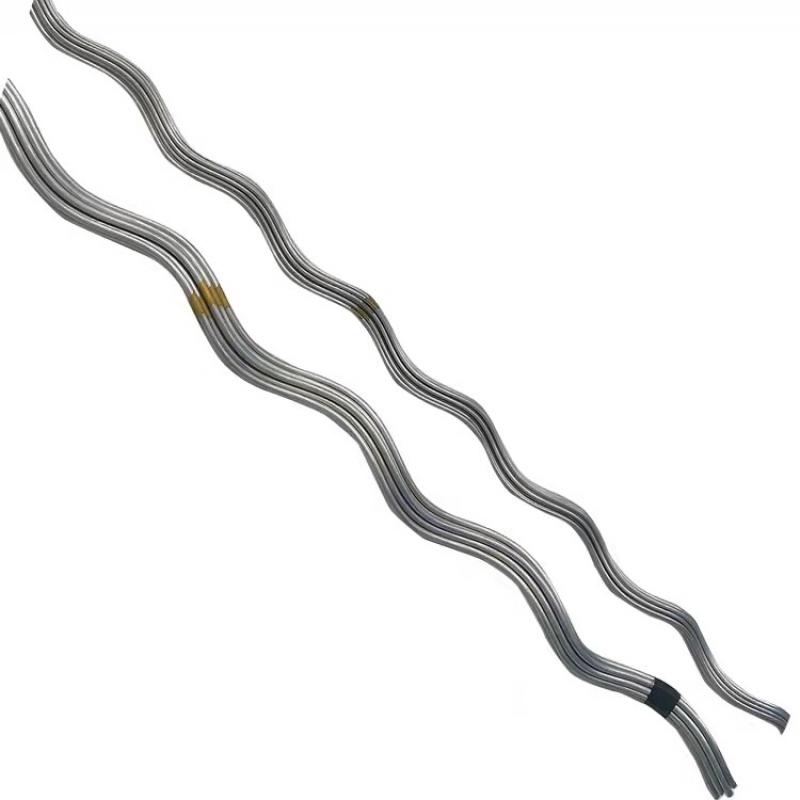

ADSS/OPGW anti-vibration hammer protective wire is a protective wire used to suppress the vibration of conductors and ground wires on overhead power lines.

Contact Now

Preformed inner protection line rods:The material is aluminum-clad steel wire, which is the same material as all the aluminum-clad steel wires of OPPC cable. The inner wall of the protector rods is glued with a layer of gold steel sand through a high-strength polymer water-soluble environmentally friendly adhesive to increase the friction with the optical cable. The rods is preformed into four sub-bundles during production, which is convenient for quick installation.

Contact Now

The preformed armor rod is used to protect the wire from vibration, clamping stress, friction, arc and all other external damage. The armor rod section protection wire can protect the wire from arc, friction or other damage on the short-span line when the wire vibration is not serious.

Contact Now

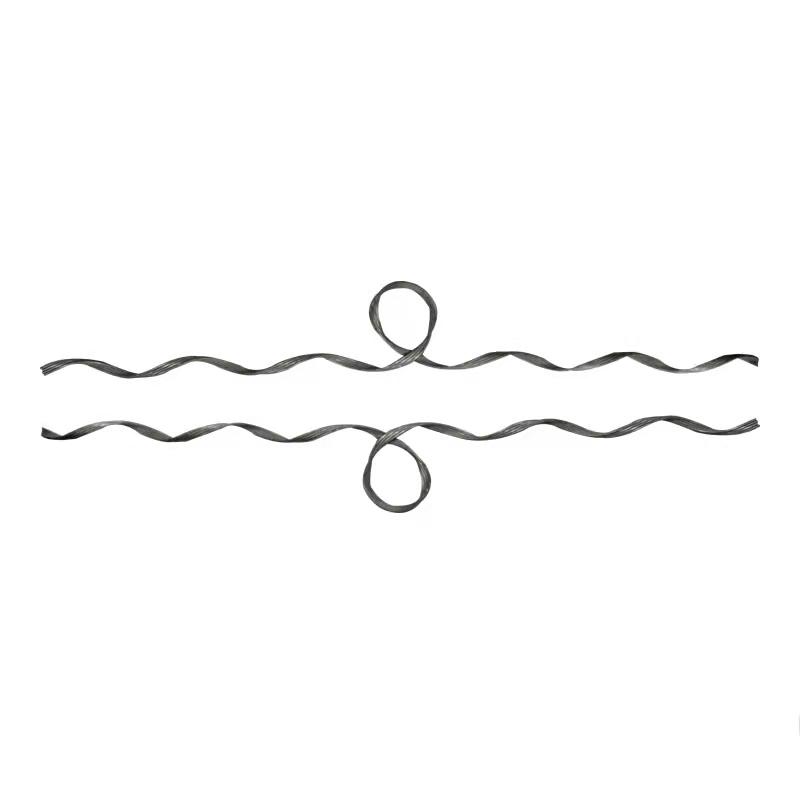

The structure of the preformed armor rod and the short protective rod is simple. A set of pre-twisted wires form an empty tube, which generates a gripping force when wrapping the wire, thereby protecting the wire. The pre-twisted wire protection line is used for vibration protection and has been included in the hardware products.

Contact Now

The OPGW grounding clamp consists of a section of aluminum alloy wire, an aluminum alloy clamp (connected to the OPGW optical cable), and all-aluminum terminal blocks (connected to the main material of the iron tower).

Contact Now

The second damper can be used for OPGW tension tower vibration dampers if necessary. Tension assembly is used for OPGW cable route's fixing and anchor shackling. Usually be installed on the terminal tower, tight tension tower and intersection angle tower.OPGW tension tower vibration dampers installation image:

Contact Now

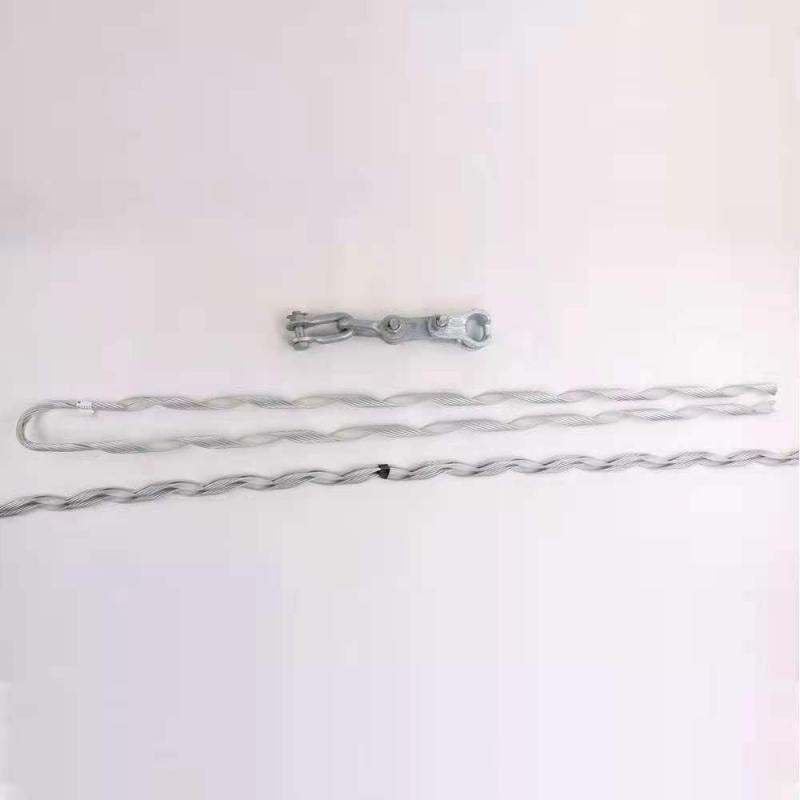

Applications 1.Tensile clamps for OPGW optical cables are mainly used to connect optical cables with a breaking strength of 160kN and below to tensile poles, corner poles and terminal poles. The complete set of OPGW optical cable strain clamp includes outer pre-twisted wires, inner pre-twisted wires, supporting connectors and grounding wires.

Contact Now

Suspension string fittings include U-shaped screws, suspension clamps, pre-twisted wire protection lines, grounding drain wires and necessary connection fittings. The mechanical strength of the hanging string connection fittings is 70kN. The suspension clamp is a pre-twisted wire type, and the clamp body is made of aluminum alloy. The clamp body should be equipped with an EPDM rubber cushioning elastic pad. The allowable value of the drape angle at the outlet of the OPGW single drape clamp is not less than 15 degrees.

Contact Now

OPGW Optical Cable Tension Fitting StringFeatures:a. Even stress distribution, no stress concentration point, can well protect the optical cable.b. Under the premise of not exceeding the lateral compression strength of the optical cable, it has a greater grip on the optical cable and can withstand greater tension.c. The grip strength of the optical cable is not less than: 95% of the ultimate tensile strength (UTS) of the optical cable, which is completely suitable for the needs of optical cable erection. Schematic diagram of product composition:Technical specification sheet

Contact Now

Fiber optic tangent used as cable suspension hardware first-rate at the identical time because the attitude of alternate, each horizontal or vertical, is a good deal much less then 15°.Armor grip suspesnion used for any span duration with an perspective change, each horizontal or vertical, a whole lot much less than 30°.There are 3 types of ADSS fitting suspension grips: 1. ADSS fitting for span length less than 70msuspension with suspention rods and protection rods, ring type thimble and pole attachment, steel tip, D shackle with related accessories. 2.

Contact Now

The protective armor rod is a metal wire that is spirally wound on the wire to increase the rigidity and vibration resistance of the wire at the winding position.

Contact Now

The grounding clamp is mainly used for the grounding of the OPGW optical cable to provide a path for short-circuit current. The grounding clamp consists of a grounding wire, a set of aluminum alloy parallel groove clamps (connecting OPGW optical cable and grounding wire) and a terminal (connecting to the iron tower). Usually, one terminal tower and linear tower are equipped, and two connecting towers are equipped.

Contact Now

The protective wire can avoid damage caused by the aluminum clamp of the anti-vibration hammer directly clamped on the 0PGW optical cable, and has a good protective effect on the optical cable. The factors that cause vibration include span, tension, wind speed, wind direction, ground wire and cable structure size, etc. Features: a. Using a unique design, its basic principle is to dynamically absorb energy, its frequency coverage is 6Hz-150Hz, and there are four resonance frequencies in this range, which can meet the needs of various types of OPGW, and has a very effective v

Contact Now

ADSS preformed tension set 200M span includes helical guy grip, protector rods, accessories like HDG U shackle, Galv.

Contact Now

ADSS spiral vibration rods is mainly used on overhead lines to eliminate or reduce the vibration of wires and optical cables under the action of laminar wind to clamp the damage to the fittings and the outer sheath of the optical cable. The anti-vibration whip is not only suitable for ADSS optical cables, but also suitable for OPGW optical cables and power transmission cables.Structural features: 1. The structure is simple, the installation is convenient, the maintenance is easy, and the installation position is not limited. 2. The spiral vibration isolator includ

Contact Now

Features: a. Even stress distribution, no stress concentration point, can well protect the optical cable. b. Under the premise of not exceeding the lateral compression strength of the optical cable, it has a greater grip on the optical cable and can withstand greater tension. c. The grip strength of the optical cable is not less than: 95% of the ultimate tensile strength (UTS) of the optical cable, which is fully suitable for the needs of optical cable erectionProduct composition diagramProduct technical specification sheet: Sn Model No.

Contact Now

FR anti-vibration hammer, optical cable anti-vibration hammer, pre-twisted anti-vibration hardware Product usage: Reduce the vibration amplitude of the wire. Applicable conductor: steel core aluminum stranded wire Process: Hot-dip galvanizingFeatures: 1.Tuning fork structure: The anti-vibration hammer adopts a special tuning fork structure, which can generate four resonant frequencies, which greatly covers the vibration frequency range of the cable in reality. 2.Real materials: The hammer head is gray cast iron, painted.

Contact Now

The preformed top tie are all designed in a spiral structure and consist of two aluminum-clad steel wires. The central part of the power distribution cable is formed in the factory, and its shape can be matched with various insulators and wires.

Contact Now

Power equipment optical cable communication 4D type protective hardware anti-vibration hammer with armor rod. Features: Due to the use of hammers with different sizes and masses, the response frequency range of traditional shock-proof hammers is expanded. Because the shapes of large and small hammers and hooks have no edges and corners, corona is reduced. In addition, the use of aluminum alloy for the hook can also reduce the energy loss of the wire.

Contact Now

Fiber optic tangent used as cable suspension hardware best at the same time as the attitude of change, each horizontal or vertical, is a good deal less then 15°.Armor grip suspesnion used for any span duration with an perspective alternate, both horizontal or vertical, a whole lot less than 30°.There are 3 types of ADSS fitting suspension grips: 1. ADSS fitting for span length less than 70msuspension with suspention rods and protection rods, ring type thimble and pole attachment, steel tip, D shackle with related accessories. 2.

Contact Now

Product advantages: 1. There is a large contact area between the clamp and the pull wire, the stress distribution is even, there is no stress concentration point, and the achievable grip strength is not less than 95% of the stranded wire Calculate the breaking force. 2. The dead end preformed guy grip is made of the same material as the pull wire, which has good corrosion resistance. 3. The dead end preformed guy grip is simple to install, without any special tools, and can be done independently by one person.

Contact Now

The structure of the preformed strain clamp is straightforward, and its pre-twisted cord legs are twisted to form an empty tube, and the rear part is a pre-formed twisted ring. the empty tube shaped via the legs of the pre-twisted twine can generate a robust grip while it's far wound at the wire, and the twisted loop is used to restore the insulator.

Contact Now

Features: 1. It has all the functions of a single suspension clamp.2.

Contact Now