Product advantages: 1. There is a large contact area between the clamp and the pull wire, the stress distribution is even, there is no stress concentration point, and the achievable grip strength is not less than 95% of the stranded wire Calculate the breaking force. 2. The dead end preformed guy grip is made of the same material as the pull wire, which has good corrosion resistance. 3. The dead end preformed guy grip is simple to install, without any special tools, and can be done independently by one person.

Contact Now

ADSS terminating helix dead end is made of aluminum-clad steel wire, and the pre-twisted wire is preformed into a bundle during processing, and a firm layer of emery is glued to the inner wall to increase the grip of the tension clamp under the condition of reducing the side pressure on the optical cable.

Contact Now

Wire tension clamp NL-50/8 for steel core aluminum stranded wire made of galvanized steel wire or alloy clad steel wire. 1. The preformed guy grip is used for the installation of ACSR conductors. The product is with much more reliability and economy compared with the bolt-type & hydraulic strain clamps. 2. The structure of the preformed guy grip is simple. When installation, the tubular structure formed by the legs of the pre-twisted wire can be naturally wound on the conductor to produce a strong grip.

Contact Now

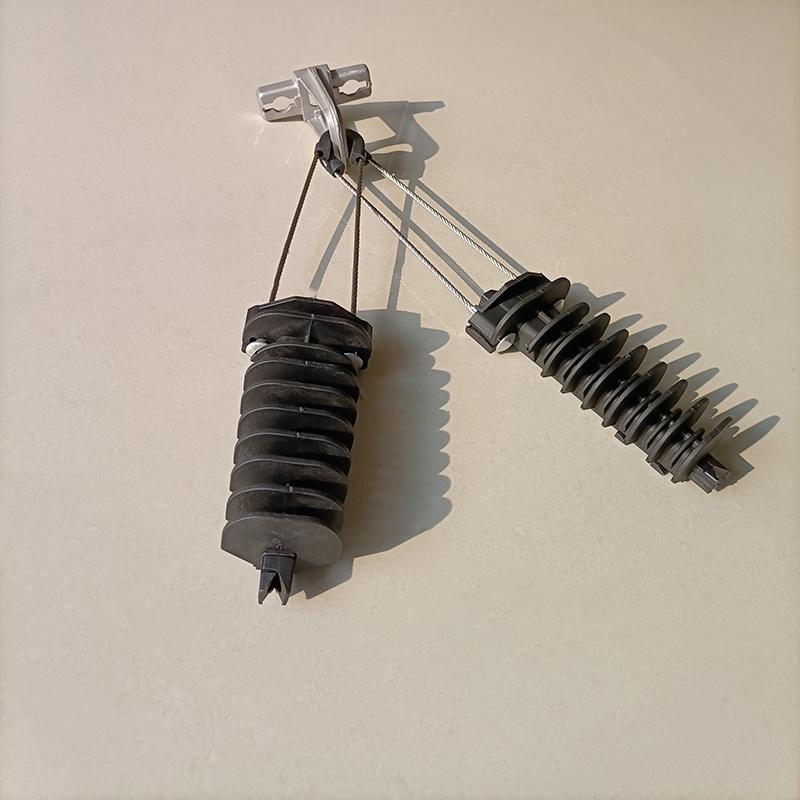

Helical tension set ADSS long span with D shackle, Thimble clevis, helical dead end, protector rods. A dead-end is installed at each end of the cable length to attach to the structures. Two dead ends are used at angle changes of 30 degree or greater, either horizontal or vertical.

Contact Now

The preformed dead end is used to fix the cable clamp of the cable of the tower, the iron tower, and the microwave tower. It can replace the U-T clamp and the wedge clamp that are commonly used to fix the cable on the line tower. The unique design makes the tension-resistant structure of the cable simple and reliable. After installation, the empty tube formed by the twisting of the two legs of the pre-twisted wire of the wire clip can be wound on the cable to produce a strong grip. The twisted ring is used to fix the ground anchor. Or on the tower pole.

Contact Now

Dead end clamp is made of plastic body with very high mechanical and climatic resistance. A stainless steel flexible cord equipped with movable insulating saddle and two sleeves compressed on the ends to prevent detachment from the clamp body.An inner sheath consisting of two insulating plastic wedges for clamping of the neutral carrier without damaging the cable insulation.

Contact Now

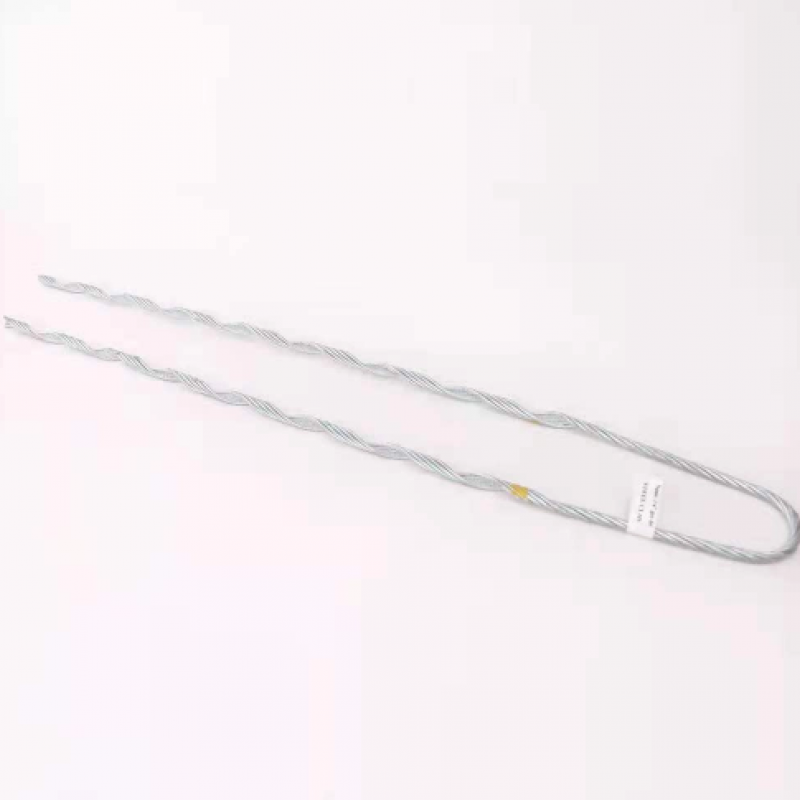

Stay grips dead ends is the preformed wire type, minimum length is 600mm and finish is galvanized. Thimbles is used with guy grips to support wires through the stay rod eye. A combination of guy grips and pole top make offs is used.Installation image:

Contact Now

1. The twisting direction of the steel stranded wire and the matching preformed guy grip needs to be the same, and the tensile strength of the galvanized steel wire is 1370N/mm2-1470N/mm2. 2. The white corundum used to increase the friction between the pre-twisted wire and the surface should meet the requirements of GB/T 2479.3. The surface of the preformed guy grip should be smooth and free of defects such as cracks, folds and scars.4. The size and tolerance of the pre-twisted wire The size of the pre-twisted wire should meet the requirements of the design d

Contact Now

Galvanized steel pole top make off is generally double wrapped around the pole. 3 strands plus king wire and effective 7 strand stay length for dead end attachment. top to facilitate termination of the stay strand that firms the pole on the earth.Features:1. Material: galvanized steel wire2. Application: for stay rod assembly3. Dimension: 1750 overall length mm4. Finish: hot dip galvanized5. Stay wire diameter: 12mm6. Tensile strength” 63kNProduction drawing: Installation image:

Contact Now

1. The preformed guy grip is used for the installation of ACSR conductors. The product is with much more reliability and economy compared with the bolt-type & hydraulic strain clamps. 2. The structure of the preformed guy grip is simple. When installation, the tubular structure formed by the legs of the pre-twisted wire can be naturally wound on the conductor to produce a strong grip. The novel structure and unique design make the wire resistant to tension.

Contact Now

Preformed inner protection line rods:The material is aluminum-clad steel wire, which is the same material as all the aluminum-clad steel wires of OPPC cable. The inner wall of the protector rods is glued with a layer of gold steel sand through a high-strength polymer water-soluble environmentally friendly adhesive to increase the friction with the optical cable. The rods is preformed into four sub-bundles during production, which is convenient for quick installation.

Contact Now

The galvanized steel strand is made of galvanized material and is composed of multiple steel wires. It has strong anti-rust, anti-rust ability, corrosion resistance, strong load-bearing, and good toughness. After multiple tensile tests, each steel wire rope has no breaks and no loose strands. The surface is smooth, burr-free, high tensile strength, and small bending radius.

Contact Now

The structure of the preformed strain clamp is simple, and its pre-twisted wire legs are twisted to form an empty tube, and the rear part is a pre-formed twisted ring. The empty tube formed by the legs of the pre-twisted wire can generate a strong grip when it is wound on the wire, and the twisted loop is used to fix the insulator.

Contact Now

Composition: inner stranded wire, outer stranded wire, embedded ring, PD type hanging plate, U type hanging ring. Purpose: To withstand full tension. Features: a.The outer stranded wire is directly connected to the pole tower through the connecting fittings such as the embedded ring, and bears the line load. b. The inner twisted wire protects the ADSS optical cable.Technical specification: -Design for quick and easy installation-Minimizing time consuming civil works -Provide a future proof aerial network-Temperature: -10°C up to +70°CSn Model No.

Contact Now

ADSS spiral helical dead end consists of an anchor shackle, thimble clevis and preformed guy grip of suitable length, which used for supporting ADSS fiber optic cable in tension at cable sections, acute turnings or at the terminal pole. -Design for quick and easy installation-Minimizing time consuming civil works -Provide a future proof aerial network-Temperature: -10°C up to +70°CSn Model No. Suitable for ADSS cable range(mm) 300M spanANZ 030/0940 8.6-9.4ANZ 030/1010 9.5-10.1ANZ 030/1070 10.2-10.7ANZ 030/1140 10.8-11.4ANZ 030/1220 11.5-12.2ANZ

Contact Now

The medium and high tension strain clamps are composed of a double-layer twisted wire structure. The tensile inner twisted wire is made of galvanized steel wire or aluminum-clad steel wire. The inner wall of the pre-twisted wire is stuck with a layer of fine emery to increase friction. The pre-twisted wire is preformed into four sub-bundles during processing to avoid installation errors and facilitate quick installation. The ends of the pre-twisted wires are bent radially outward to avoid squeezing and damaging the optical cable.

Contact Now

Galvanized steel thimble clevis is compatible with dead end application to attach loop type dead end to tongue or eye type fittings. It is usually ductile iron material, hot dip galvanized and with 5/8” dia clevis pin.

Contact Now

The preformed top tie are all designed in a spiral structure and consist of two aluminum-clad steel wires. The central part of the power distribution cable is formed in the factory, and its shape can be matched with various insulators and wires.

Contact Now

The structure of the preformed armor rod and the short protective rod is simple. A set of pre-twisted wires form an empty tube, which generates a gripping force when wrapping the wire, thereby protecting the wire. The pre-twisted wire protection line is used for vibration protection and has been included in the hardware products.

Contact Now

ADSS spiral helical dead end consists of an anchor shackle, thimble clevis and preformed guy grip of suitable length, which used for supporting ADSS fiber optic cable in tension at cable sections, acute turnings or at the terminal pole. -Design for quick and easy installation-Minimizing time consuming civil works -Provide a future proof aerial network-Temperature: -10°C up to +70°CSn Model No. Suitable for ADSS cable range(mm) 300M spanANZ 030/0940 8.6-9.4ANZ 030/1010 9.5-10.1ANZ 030/1070 10.2-10.7ANZ 030/1140 10.8-11.4ANZ 030/1220 11.5-12.2ANZ

Contact Now

Features: 1.Tuning fork structure: The anti-vibration hammer adopts a special tuning fork structure, which can generate four resonant frequencies, which greatly covers the vibration frequency range of the cable in reality. 2.Real materials: The hammer head is gray cast iron, painted. Anti-oxidation, corrosion resistance and long service life. 3.Various types of anti-vibration hammers: You can choose freely according to your needs.The anti-vibration hammer is designed to reduce the vibration of the wire due to wind.

Contact Now

The hot-dip galvanized hexagonal nut has spiral thread: the thread has a fastening effect, the nut has a smooth cross section, no residual burr, and the thread is neat and clear; smooth and no burr: smooth and bright surface, uniform force, non-slip silk; wear-resistant and high-corrosion resistance : The surface is galvanized, which is not easy to rust.

Contact Now

Galvanized ball eyes is a ball head hanging ring with a protective layer. The characteristic of the ball head hanging ring is to avoid direct impact between the metal ball head and the insulator.Technical sheets:

Contact Now

The thimble clevis is mainly for ADSS light span tension set which made of galvanized ductile iron.All dielectric dead-ends require a proper size and strength thimble clevis or extension link.Technical characteristics:Model No.: TC-02Associated Bolt size: M14Tension strength: 20KNFinish: hot dip galvanized steelCotter pin: stainless steelDrawing: Installation image(part 2):

Contact Now