Cable Fitting End Clamp For OPGW

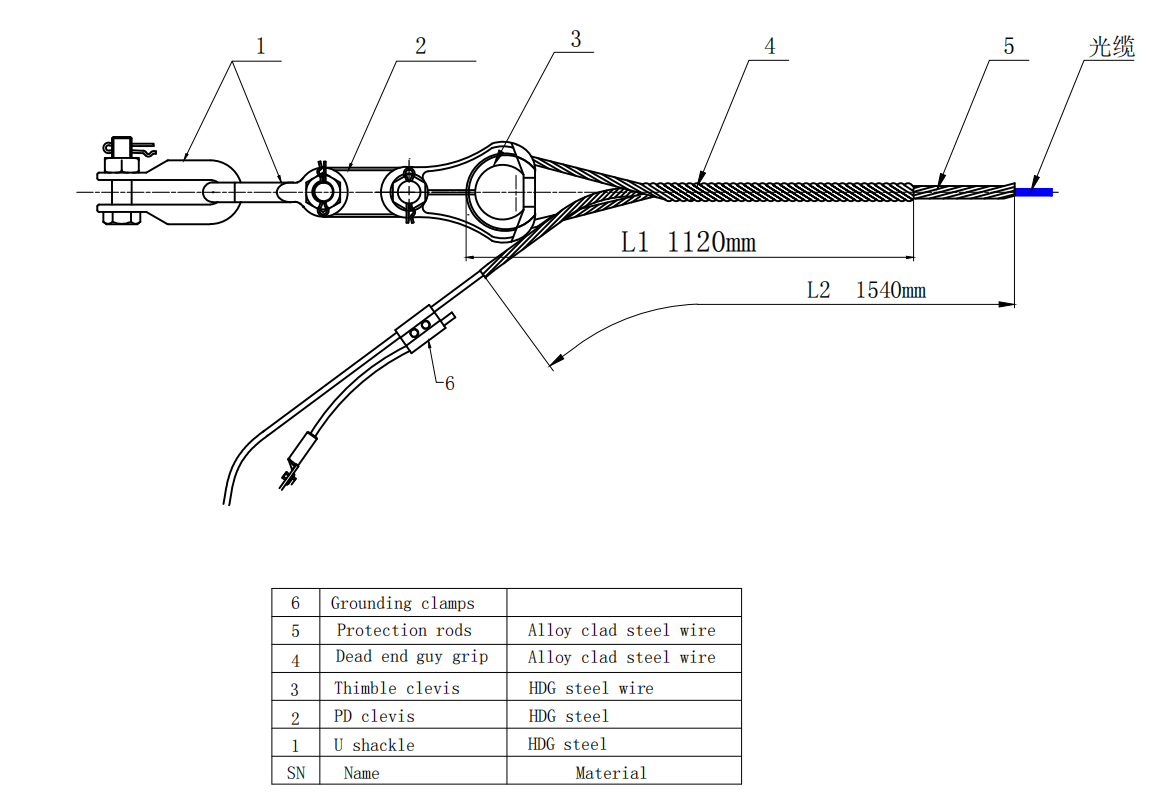

The pre-twisted wire tension clamp for OPGW optical cable is composed of inner stranded wire, outer stranded wire, embedded ring, PD-type hanging plate, U-type hanging ring, etc.

Purpose: To withstand full tension. Connect the optical fiber composite ground wire to the terminal, tensile strength (rotation angle greater than 25°) or the optical cable connection pole.

OPGW Optical Cable Tension Fitting String

Features:

a. Even stress distribution, no stress concentration point, can well protect the optical cable.

b. Under the premise of not exceeding the lateral compression strength of the optical cable, it has a greater grip on the optical cable and can withstand greater tension.

c. The grip strength of the optical cable is not less than: 95% of the ultimate tensile strength (UTS) of the optical cable, which is completely suitable for the needs of optical cable erection.

Schematic diagram of product composition:

Technical specification sheet:

Sn | Model No. | Suitable cable range(mm) |

1 | ONY 0780 | 7.2-7.8 |

2 | ONY 0880 | 7.9-8.8 |

3 | ONY 1010 | 8.9-10.1 |

4 | ONY 1140 | 10.2-11.4 |

5 | ONY 1280 | 11.5-12.8 |

6 | ONY 1410 | 12.9-14.1 |

7 | ONY 1550 | 14.2-15.5 |

8 | ONY 1730 | 15.6-17.3 |

9 | ONY 1920 | 17.4-19.2 |

10 | ONY 2110 | 19.3-21.1 |

Purchase notice:

a. According to the ultimate tensile strength and outer diameter of the OPGW cable, select the appropriate tension clamp.

b. Quantity configuration: 1 set/terminal pole tower (including gantry); 2 sets/tensile pole tower, turning angle greater than 25° and OPGW connecting tower.

c. The standard configuration of the clamp is right-handed according to the twisting direction of the outer layer of the OPGW optical cable. If the twisting direction of the outer layer of OPGW cable is left-handed, it should be indicated in the order contract.

d. It is recommended to use this clamp once after it has been under full tension.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible