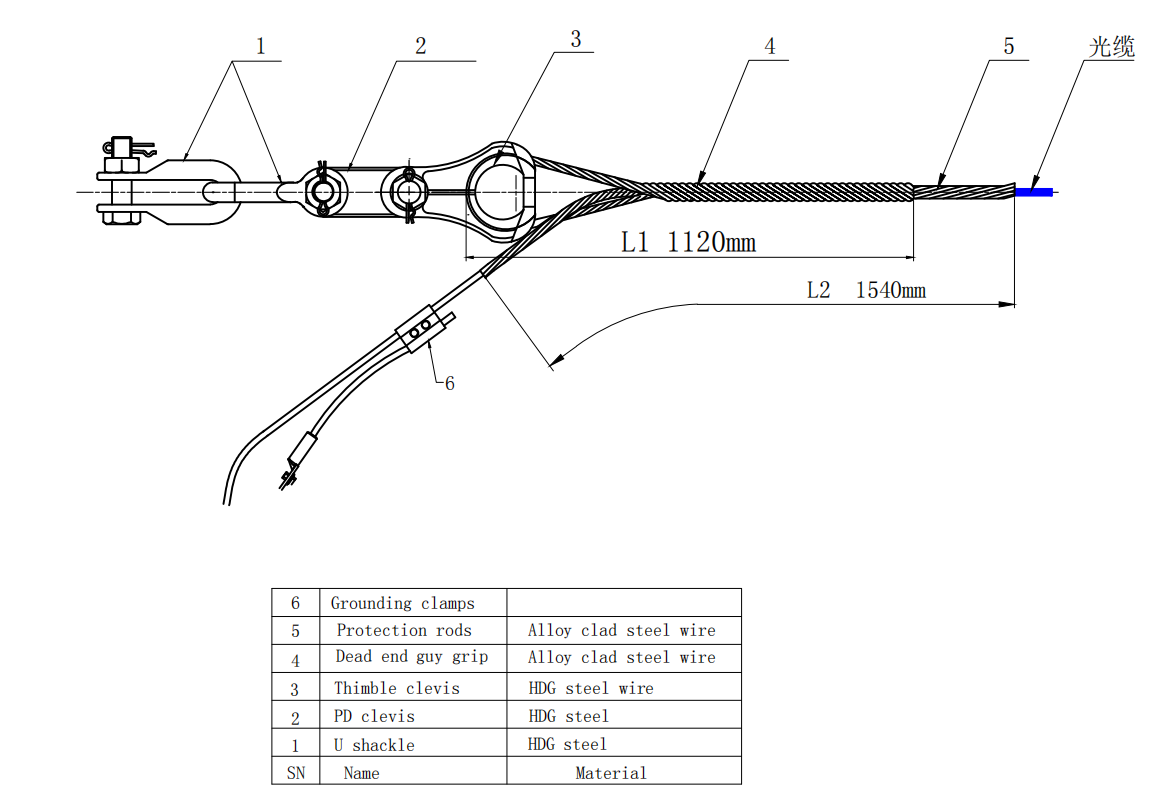

Transmission Line OPGW Tension Set

Installation of OPGW tensile hardware:

Composition: inner stranded wire, outer stranded wire, embedded ring, PD type hanging plate, U type hanging ring, etc. This strain clamp is suitable for the strain tower of the line. In order to ensure the integrity and reliability of the tension clamp function, in principle, the pre-twisted wire clamp can only be used for a permanent and safe use, and it is generally not allowed to use it repeatedly. Unless it is only used as a "towing fixture" to tow the optical cable. In order to ensure good performance and personal safety, it is necessary to clarify whether the model and specifications of the fittings are consistent with the requirements of the optical cable before use.

Composition: inner stranded wire, outer stranded wire, embedded ring, PD type hanging plate, U type hanging ring, etc.

Purpose: To withstand full tension. Connect the optical fiber composite ground wire to the terminal, tensile strength (rotation angle greater than 25°) or the optical cable connection pole.

Features: a. The stress distribution is uniform and there is no stress concentration point, which can protect the optical cable well.

b. Under the premise of not exceeding the lateral compression strength of the optical cable, it has a greater grip on the optical cable and can withstand greater tension.

c. The grip strength of the optical cable is not less than: 95% of the ultimate tensile strength (UTS) of the optical cable, which is completely suitable for the needs of optical cable erection.

Product composition diagram

Product technical specification sheet:

Sn | Model No. | Cable range |

1 | ONY 0780 | 7.2-7.8 |

2 | ONY 0880 | 7.9-8.8 |

3 | ONY 1010 | 8.9-10.1 |

4 | ONY 1140 | 10.2-11.4 |

5 | ONY 1280 | 11.5-12.8 |

6 | ONY 1410 | 12.9-14.1 |

7 | ONY 1550 | 14.2-15.5 |

8 | ONY 1730 | 15.6-17.3 |

9 | ONY 1920 | 17.4-19.2 |

10 | ONY 2110 | 19.3-21.1 |

Installation steps:

1. Align the installation mark of the outer wire with the optical cable and mark the installation.

2. Align the first set of inner wire marks with the optical cable marks.

3. The third group does the same as the second group.

4. All the inner wires are installed.

5. Align the outer wire installation mark with the inner wire installation mark.

6. Wrap one leg first.

7. Wind the other leg again.

8. Wrap the end of the outer wire well.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible