Cable Down Lead Clamp

The lead-down clamp is mainly used for the fixed installation of ADSS and OPGW optical cables when they are lead on the tower. For example, at the fiber optic cable joint pole (tower), the fiber optic cable is led from the clamping hardware to the installation location of the splice protection box; the fiber optic cable is led down from the pole to the underground pipeline, cable trench, buried directly, and led down into the machine room, etc. Fixed. Prevent the optical cable from rubbing against the tower or other objects under the action of wind to damage the optical cable, so as to protect the safety of the optical cable.

ADSS optical cable tower with down-lead clamp, optical cable clamp, fixed optical cable clamp.

The lead-down clamp is used to lead down the optical cable and fix the optical cable when it is jumpered, which improves the mechanical performance of the clamp. It is mainly used for the communication line of the newly built overhead high-voltage power transmission system of 35kv and above. The stainless steel tube and cable core stranding design is reasonable, and the optical fiber is redundant. The length is accurate; the all-dielectric self-supporting optical cable (adss) is suspended on the pole tower with the line turning angle less than 25°

Features:

1.Wide range of application: It is suitable for skeleton type, layer stranded type, beam tube type armored and non-armored fiber optic cables, and is flexible in use.

2. Dielectric strength: 15kv DC, no breakdown in 2 minutes.

3.Function of the down-lead clamp for the stainless steel belt-shaped pole: fasten the optical cable that is drawn down or up from the pole to the pole so that it cannot be shaken, so as to avoid the abrasion of the optical cable.

4.Conditions: the first and end poles, connecting poles, etc. of the optical cable line.

5.Usage: Generally install one every 1.5 meters.

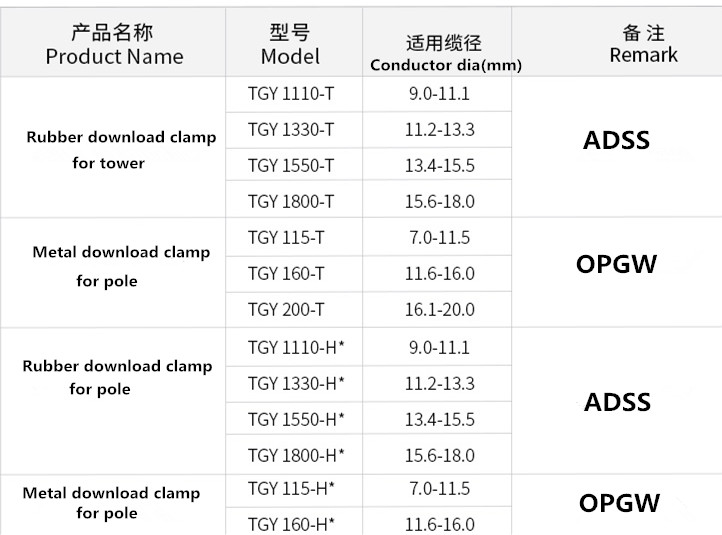

Technical specification table:

Related News

Submitted successfully

We will contact you as soon as possible