Suspension Clamp Set For OPGW

1) The function of the pre-twisted suspension clamp is similar to that of the ordinary suspension clamp, which is used to suspend the conductor and the ground wire on the tower. The difference is that the pre-twisted suspension clamp can not only protect the wire, but its smooth outer contour greatly reduces corona discharge, so it is especially suitable for ultra-high voltage (220KV and above) lines. The double fulcrum pre-twisted suspension clamp can also be used for long-distance transmission lines across rivers and towers with large turning angles (30°~60°);

2) Pre-twisted suspension clamps are used for aluminum-based series conductors, aluminum-clad steel and galvanized steel strands. It is designed to weaken the static and dynamic stress on the supporting point in order to protect the conductor and stranded wire, Resist the impact of vibration, and at the same time protect the wire from impact and arc on the supporting point;

3) The pre-twisted suspension clamp, as a kind of protective wire-suspension combination, can protect the wire from bending stress and compressive stress, and also protect the wire from abrasion.

The wire clamp is composed of a rubber clamp block, a pre-twisted wire and a cast aluminum casing.

1. Enhance the rigidity of the cable hanging point and increase the radius of curvature. The single-line clamp can meet the 30° steering angle, and the double-line clamp can meet the 60° steering angle.

2. It can be ensured that the cable is not subject to large bending stress near the outlet of the wire clamp, so as to avoid local mechanical damage causing strand break or wire breakage.

3. Improve the vibration resistance of the clamp itself, which can better protect the cable and extend the life of the system.

4. The spiral structure of the pre-twisted wire increases the grip strength of the clamp, which can reach more than 20 UTS, and has good dynamic stress tolerance.

5. It can provide enough grip to protect the cable from running safely under long-term unbalanced load conditions.

6. The pre-twisted wire and the clamp body are made of aluminum alloy, which is a non-magnetic material, with small magnetic loss, and strong anti-corrosion and mechanical properties.

7. The ends of the pre-twisted wire are rounded, and the overall shape of the clamp is smooth and the corona is small. 8. The suspension clamp has a larger contact area with the cable, the stress is evenly distributed, and there is no stress concentration point, which provides better protection.

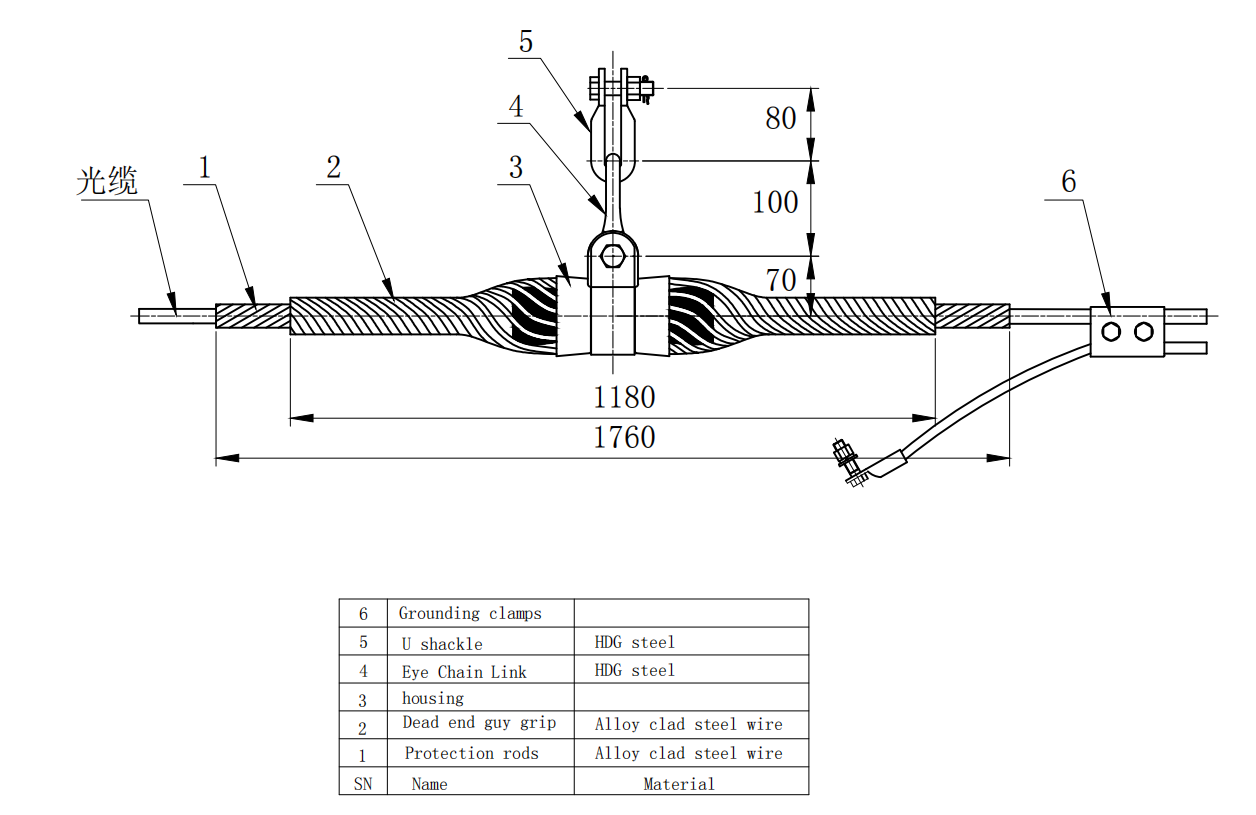

Product composition diagram:

Product technical specification sheet:

Sn | Model No. | Suitable cable range(mm) | Inner rod | Outer rods |

1 | OCL 0800 | 7.4-8.0 | Aluminum alloy wire Φ3.7 | Aluminum alloy wire Φ5.18 |

2 | OCL 0880 | 8.1-8.8 | ||

3 | OCL 0960 | 8.9-9.6 | ||

4 | OCL 1010 | 9.7-10.1 | ||

5 | OCL 1060 | 10.2-10.6 | ||

6 | OCL 1110 | 10.7-11.1 | ||

7 | OCL 1160 | 11.2-11.6 | ||

8 | OCL 1170 | 11.7 | Aluminum alloy wire Φ4.3 | Aluminum alloy wire Φ6.3 |

9 | OCL 1200 | 11.8-12.0 | ||

10 | OCL 1270 | 12.1-12.7 | ||

11 | OCL 1290 | 12.8-12.9 | ||

12 | OCL 1360 | 13.0-13.6 | ||

13 | OCL 1410 | 13.7-14.1 | ||

14 | OCL 1430 | 14.2-14.3 | ||

15 | OCL 1450 | 14.4-14.5 | ||

16 | OCL 1510 | 14.6-15.1 | ||

17 | OCL 1580 | 15.2-15.8 | ||

18 | OCL 1600 | 15.9-16.0 | ||

19 | OCL 1690 | 16.1-16.9 | ||

20 | OCL 1730 | 17.0-17.3 | ||

21 | OCL 1800 | 17.4-18.0 | ||

22 | OCL 1840 | 18.1-18.4 |

Safety Note

The direction of rotation of the clamp and the outer layer of the wire is the same, and the standard is right-handed. If left-handed is required, it should be indicated in the order contract.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible