Line Fitting XGH Suspension Clamp

XGH suspension clamps are mainly used for overhead power lines or substations, to fix the wires on the insulator string, and hang the wire lightning protection wire on the insulator or the lightning protection wire on the tower by connecting the fittings. The clamp body and the pressing plate are made of high-strength aluminum alloy, and have undergone a heat treatment process, which has no hysteresis effect and has an energy-saving effect.

The aluminum alloy suspension clamp is firm, easy to install, sturdy and durable, and adopts low-pressure casting technology; it has strong corrosion resistance, no hysteresis, not easy to break, and strong electrical conductivity.

Features:

1. Material: high strength alloy aluminum

2. Model No.: XGH-3

3. U bolt number: 2 nos bolts

4. Tension strength: 40kN

Technical specification:

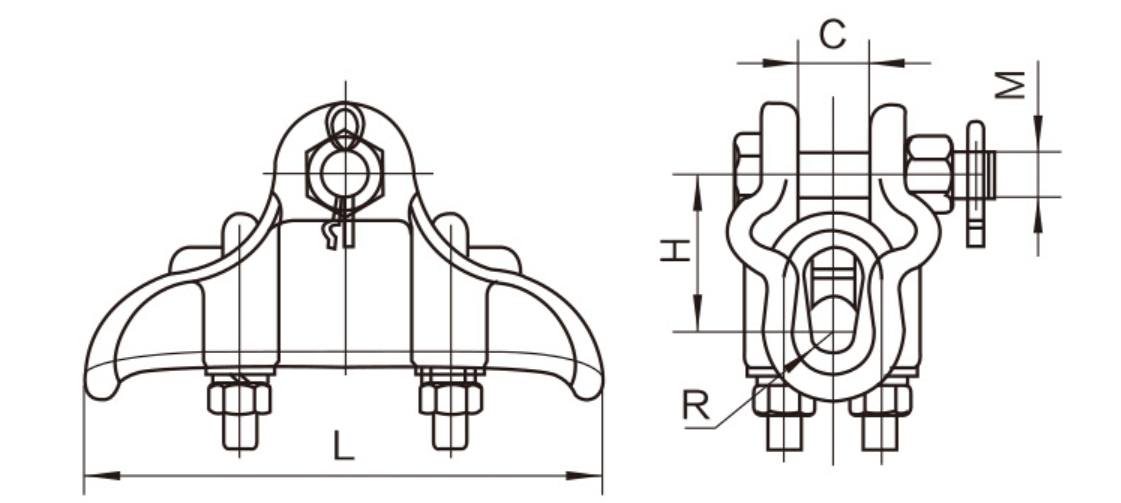

model | Adapt to wire diameter(mm) | Main dimensions(mm) | Nominal failure load(KN) | reference weight(kg) | ||||

H | C | M | R | L | ||||

XGH-2 | 5.1~12.5 | 52.5 | 25 | 16 | 18.0 | 166 | 40 | 1.0 |

XGH-3 | 12.4~17 | 50.5 | 23 | 16 | 11.5 | 200 | 40 | 1.5 |

XGH-4 | 19~23.5 | 59.5 | 27 | 16 | 13.5 | 225 | 40 | 2.3 |

XGH-5 | 24.2~28 | 70 | 32 | 16 | 16.0 | 260 | 60 | 4.4 |

Installation method:

1. Select and install the correct model of the wire, and install it.

2. Connect the wire clip with other connecting fittings.

3. Loosen the U-shaped bolt and nut to pass the wire through the suspension clamp, and adjust the wire sag with a wire tensioner.

4. Tighten the nuts on both sides of the U-bolt evenly, keep the pressure bar in the middle of the pressure groove of the body, and press the wire on the body.

5. Use the wire tightener to pay off and the installation is complete.

Related News

Submitted successfully

We will contact you as soon as possible