Armour Rod For 67sqmm Quail

The preformed armor rod is used to protect the wire from vibration, clamping stress, friction, arc and all other external damage. The pre-twisted short protective wire can protect the wire from arc, friction or other damage on the short-span line when the wire vibration is not serious. They can also be used as repair strips to repair damaged wires and restore their original mechanical strength and conductivity.

The protective armor rod is a metal wire that is spirally wound on the wire to increase the rigidity and vibration resistance of the wire at the winding position. In order to prevent the suspension point of the overhead power line from being damaged by vibration, the protective wire is installed at the clamp of the line conductor to increase the rigidity near the clamp, suppress the bending and extrusion stress and abrasion of the conductor due to vibration, and improve the conductor Vibration resistance.

Features

1) Less wear: Since the guard wire and the short guard wire hold the wire tightly, the wire slippage is avoided, so the wire abrasion can be reduced to a minimum;

2) Anti-loosening: Because the preformed armor rod wire has tight grip elasticity, it can guarantee *not loose;

3) Good corrosion resistance: the lines are treated with rust prevention to ensure strong corrosion resistance;

4) Simple installation: without any tools, it can be quickly and easily installed on site with bare hands, which can be completed by one person;

5) The installation quality is easy to guarantee: no special training is required, the naked eye can be inspected, and the appearance is simple and beautiful;

6) Strong general performance: It can be used with a variety of fittings.

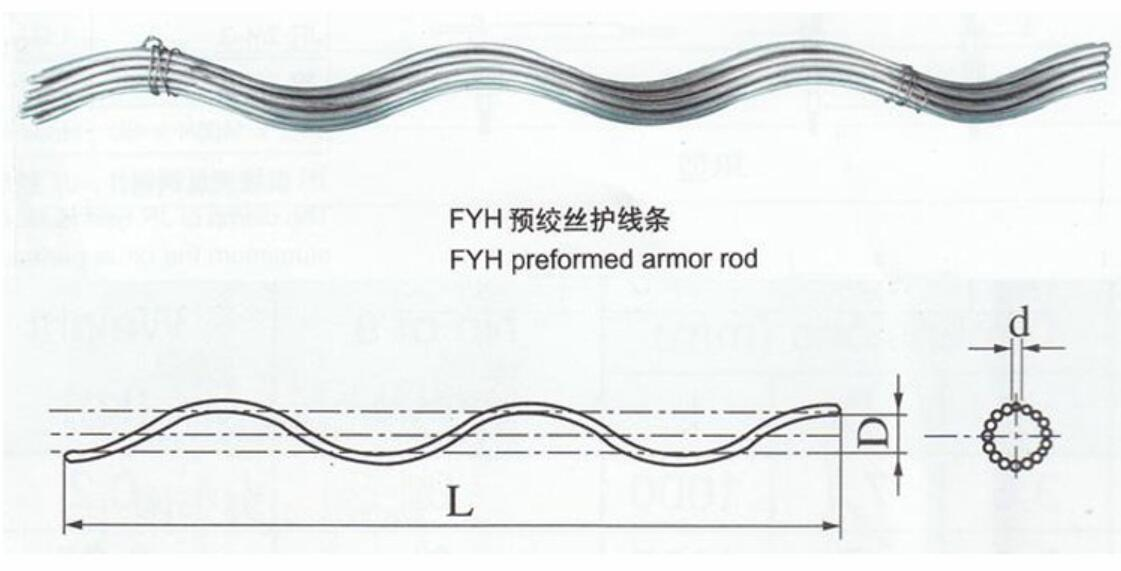

The main dimensions of the pre-twisted wire conform to the following figure and Table 1-2.

Table 1

Model No. | Overall diameter(mm) | d(mm) | D(mm) | Length(mm) | No of per set |

FYB-95/15 | 13.61 | 3.6 | 11.4 | 420 | 13 |

FYB-95/20 | 13.87 | 3.6 | 11.4 | 420 | 13 |

FYB-95/55 | 16.00 | 3.6 | 13.3 | 420 | 16 |

FYB-120/7 | 14.50 | 3.6 | 12.0 | 450 | 14 |

FYB-120/20 | 15.07 | 3.6 | 12.5 | 450 | 14 |

FYB-120/25 | 15.74 | 3.6 | 13.0 | 450 | 14 |

FYB-150/8 | 16.00 | 3.6 | 13.3 | 480 | 16 |

FYB-150/20 | 16.67 | 3.6 | 14.7 | 480 | 16 |

FYB-150/25 | 17.10 | 3.6 | 14.2 | 480 | 16 |

FYB-150/35 | 17.50 | 3.6 | 14.5 | 480 | 16 |

Table 2

Model No. | Conductor | d (mm) | D (mm) | Length (mm) | Strand number | Weight (Kg) | |

Size | Overall diameter(mm) | ||||||

FYH-95/15 | LGJ-95/15 | 13.61 | 3.6 | 11.4 | 1400 | 13 | 0.53 |

FYH-95/20 | LGJ-95/20 | 13.87 | 11.4 | 0.54 | |||

FYH-95/55 | LGJ-95/55 | 16 | 13.3 | 1500 | 16 | 0.62 | |

FYH-120/7 | LGJ-120/7 | 14.5 | 3.6 | 12 | 1400 | 14 | 0.55 |

FYH-120/20 | LGJ-120/20 | 15.07 | 12.5 | 0.57 | |||

FYH-120/25 | LGJ-120/25 | 15.74 | 13 | 0.58 | |||

FYH-120/70 | LGJ-120/70 | 18 | 4.6 | 14.9 | 1800 | 0.75 | |

FYH-150/8 | LGJ-150/8 | 16 | 3.6 | 13.3 | 1500 | 16 | 0.62 |

FYH-150/20 | LGJ-150/20 | 16.67 | 13.7 | 0.65 | |||

FYH-150/25 | LGJ-150/25 | 17.1 | 14.2 | 0.64 | |||

FYH-150/35 | LGJ-150/35 | 17.5 | 14.5 | 0.66 | |||

FYH-185/10 | LGJ-185/10 | 18 | 4.6 | 14.9 | 1800 | 14 | 1.24 |

FYH-185/25 | LGJ-185/25 | 18.9 | 15.7 | 1.25 | |||

FYH-185/30 | LGJ-185/30 | 18.88 | 15.7 | 1.25 | |||

FYH-185/45 | LGJ-185/45 | 19.6 | 16.3 | 1.26 | |||

The meanings of letters and numbers in the models in the table are: -Protection; Y--pre-twisted wire; H--protection line; B--repair strip; number--applicable wire cross section; numerator represents aluminum cross section; denominator represents steel cross section.

technical requirement:

1 The general technical conditions of preformed armor rod shall comply with the provisions of GB2314-85 "General Technical Requirements for Electric Power Fittings".

2 The preformed rod wire adopts LF-10 aluminum alloy wire according to GB3196-82, and its tensile strength is not less than 264.7N/mm² (264.7MPa).

3 The end of the preformed armor wire should be smooth hemispherical.

4 The surface of the preformed armor rod wire should be free of cracks, burrs and severe scratches.

Acceptance rules and experimental methods:

The acceptance and test of pre-twisted wire are carried out in accordance with GB2317-85 "Acceptance Rules, Test Methods, Marking and Packaging of Electric Power Fittings".

Logo and packaging:

In addition to the marking and packaging of pre-twisted wires in accordance with GB2317-85, each group of pre-twisted wires should be provided with labels such as model number, gross weight, and packaging size.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible