Spool Tie Insulator Helical Plastic

The preformed top tie is particularly used for binding among insulators and overhead insulated wires and bare wires in overhead lines of 10 kv and beneath.

The energy distribution top tie can be used to fix naked or insulated wires inside the top grooves of pin insulators and submit insulators of the power distribution device. the binding wire can restore the wire in the top groove and the facet groove.

According to different binding positions and methods, it can be divided into:

1. top tie preformed

2. Single side tie preformed

3. Double side tie preformed

4. Double top tie line

Item name | Model | Cable range | Length(mm) |

top tie preformed | TTF-1202 | φ18.57~23.37 | 580 |

TTF-1203 | φ23.39~27.90 | 660 | |

TTF-1204 | φ27.97~33.02 | 770 | |

TTF-11373 | φ34.2~37.02 | 770 | |

Single side tie preformed | SSF-2202 | φ18.57~23.37 | 750 |

SSF-2203 | φ23.39~27.94 | 660 | |

SSF-2204 | φ27.97~33.02 | 760 | |

SSF-2206 | φ33.05~38.10 | 830 | |

Double side tie preformed | DBST-2175 | φ21.74~24.59 | 480 |

DBST-2460 | φ24.61~27.84 | 495 | |

DBST-2785 | φ27.86~31.50 | 505 | |

DBST-3150 | φ31.52~35.61 | 520 | |

Double top tie line | DSTCF-2175 | φ21.74~24.59 | 490 |

DSTCF-2460 | φ24.61~27.84 | 490 | |

DSTCF-2785 | φ27.86~31.50 | 540 | |

DSTCF-3140 | φ31.52~35.61 | 540 |

Features of pre-twisted wire binding:

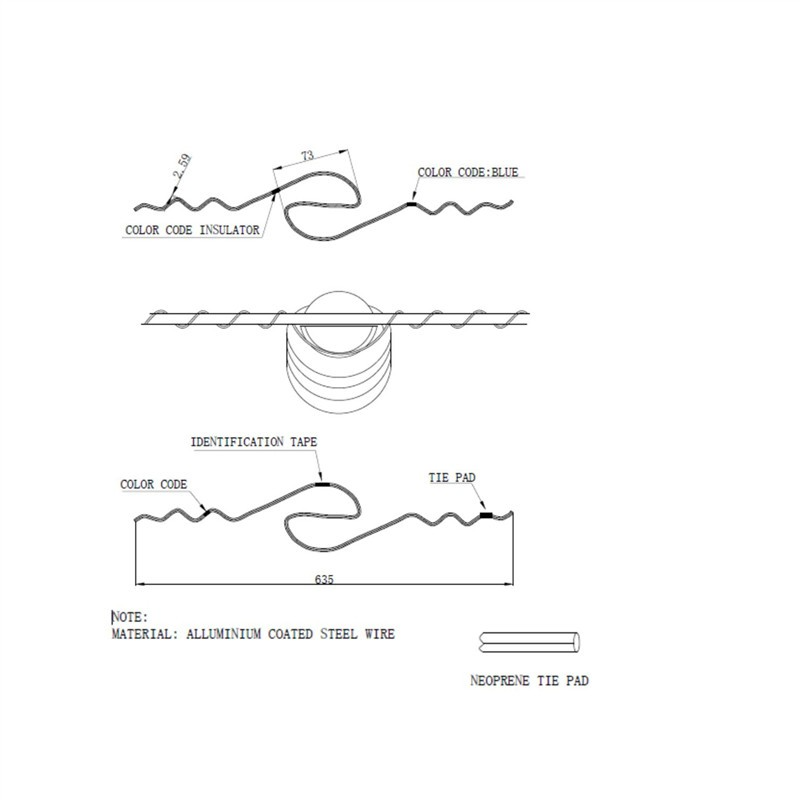

1. Long life, the binding wire is made of aluminum-clad steel material, forming an aluminum oxide film, and has good corrosion resistance.

2. High strength, 8 to 18 times that of aluminum binding wire, and more than three times that of copper binding wire.

3. Great grip, 0 to 350 kg can be customized at will.

4. Fast installation with bare hands. It only takes ten seconds to tie a porcelain bottle.

5. No eddy current or current is generated. After the porcelain bottle is tied to the overhead insulated wire, because it is a spiral, the secondary closed coil cannot be formed, and no induced current is generated.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible