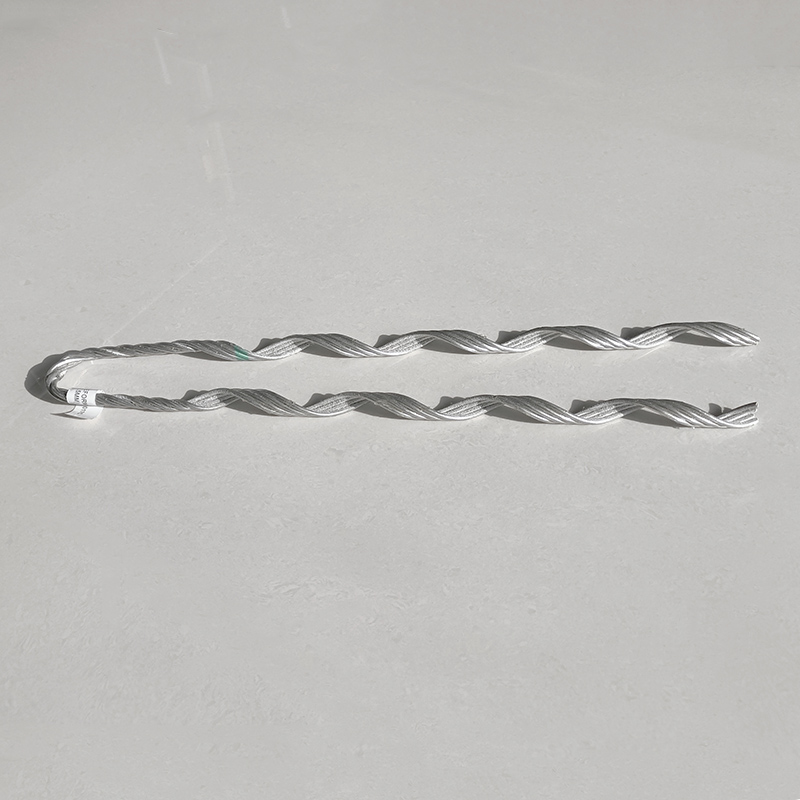

PASS PREFORMED FO ADSS

A.The guy grip clamp has high strength and can grip firmly. The grip strength of the clamp is not more than 95% CUTS (calculated breaking force of stranded wire).

B.The stress distribution of the guy grip clamp to the stranded wire is even, without damaging the stranded wire, which improves the anti-vibration ability of the stranded wire and greatly extends the service life of the wire.

C.Simple installation for easy construction. construction time be shorten a lot, without any special tools, one person can complete the operation.

D.The installation quality of the guy grip clamp is easy to guarantee, and the inspection can be carried out with sight without special training.

E.Good corrosion resistance, use high-quality materials. The material is exactly the same as the wire, ensuring that the wire clamp has strong resistance to chemical corrosion.

1.The preformed guy grip is used for the installation of ACSR conductors. The product is with much more reliability and economy compared with the bolt-type & hydraulic strain clamps.

2. The structure of the preformed guy grip is simple. When installation, the tubular structure formed by the legs of the pre-twisted wire can be naturally wound on the conductor to produce a strong grip. The novel structure and unique design make the wire resistant to tension. The guy grip clamp has reliable performance, made of galvanized steel.

Using tips:

1.Due to the special structure of the guy grip, only be used once after being stressed, and cannot be reused.

2.The specification and model of the guy grip must be provided when an inquiry.

3.It is not allowed to overlap on the guy grip, but it is allowed to overlap the conductors& cables.

4.The lay direction between the guy grip and the conductor & cables should be consistent. In general, we do right-hand direction mostly, if you need left-handed guy grip, please be kindly inform in advance and we customize.

| Sn | Model No. | Suitable for conductor range(mm) | Conductor type | |

| Min | Max | |||

| 1 | NL-35/6 | 7.35 | 8.26 | 35/6 |

| 2 | NL-50/8 | 9.26 | 10.39 | 50/8 |

| 3 | NL-70/10 | 10.4 | 11.68 | 70/10 |

| NL-50/30 | 50/30 | |||

| 4 | NL-70/40 | 13.12 | 14.66 | 70/40 |

| NL-95/15 | 95/15 | |||

| NL-95/20 | 95/20 | |||

| NL-120/7 | 120/7 | |||

| 5 | NL-120/20 | 14.67 | 16.59 | 120/20 |

| NL-95/55 | 95/55 | |||

| NL-120/25 | 120/25 | |||

| NL-185/8 | 185/8 | |||

| 6 | NL-150/20 | 16.6 | 18.77 | 150/20 |

| NL-120/70 | 120/7 | |||

| NL-150/25 | 150/25 | |||

| NL-150/35 | 150/35 | |||

| NL-185/10 | 185/10 | |||

| 7 | NL-185/25 | 18.78 | 21.26 | 185/25 |

| NL-185/30 | 185/30 | |||

| NL-210/10 | 210/10 | |||

| NL-185/45 | 185/45 | |||

| NL-210/25 | 210/25 | |||

| NL-210/35 | 210/35 | |||

| NL-210/50 | 210/50 | |||

| 8 | NL-240/30 | 21.27 | 24.05 | 240/30 |

| NL-240/40 | 240/40 | |||

| NL-240/55 | 240/55 | |||

| NL-300/15 | 300/15 | |||

| NL-300/20 | 300/20 | |||

| NL-300/25 | 300/25 | |||

| NL-300/40 | 300/40 | |||

| 9 | NL-300/50 | 24.06 | 27.2 | 300/50 |

| NL-300/70 | 300/70 | |||

| NL-400/20 | 400/20 | |||

| NL-400/25 | 400/25 | |||

| NL-400/35 | 400/35 | |||

| 10 | NL-400/50 | 27.21 | 30.78 | 400/50 |

| NL-400/65 | 400/65 | |||

| NL-400/95 | 400/95 | |||

| NL-500/35 | 500/35 | |||

| NL-500/45 | 500/45 | |||

| NL-500/65 | 500/65 | |||

Related News

Submitted successfully

We will contact you as soon as possible