ADSS Optical Cable Spiral Anti-vibration Whip

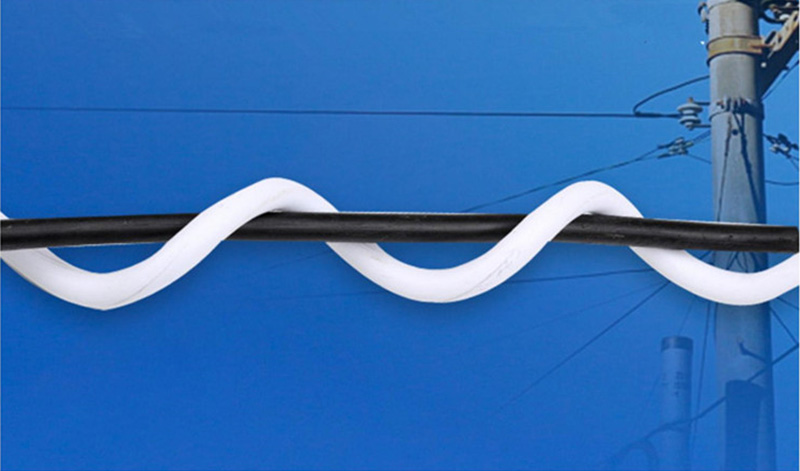

The spiral anti-vibration rod is made of material with high-strength, anti-aging, high-elasticity, and flame-retardant solid polyvinyl chloride, which is convenient and quick to install. The spiral anti-vibration rods can produce a reverse movement relative to the movement of the wire/ground wire when the wire/ground wire vibrates, thereby reducing the vibration amplitude of the wire under various vibration frequencies, thereby suppressing vibration of the wire thus protects the wire.

Structural features:

1.The anti-vibration rod will not cause the stress concentration of the wire, nor damage the wire, to avoid corrosion or arcing.

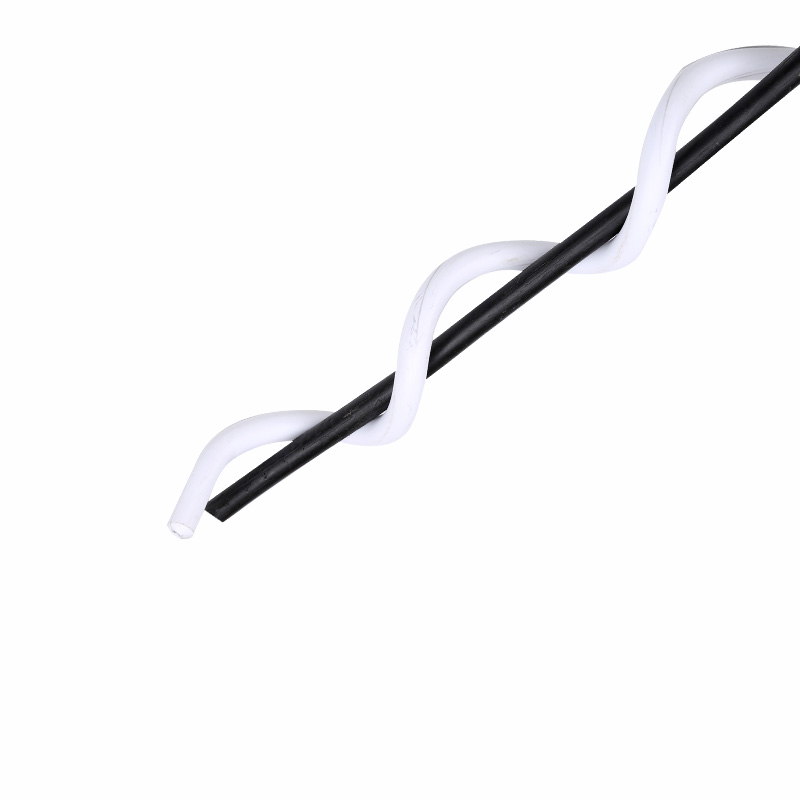

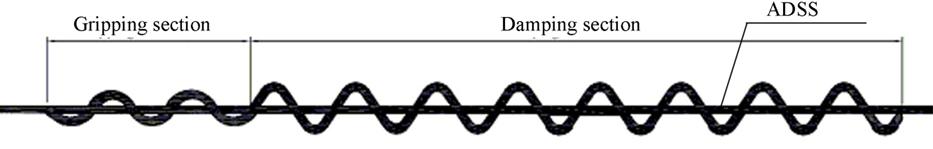

2.The spiral anti-vibration rod is composed of a short gripping section and a long damping section.

3.The gripping section can effectively hold the cable and firmly fix it on the cable. At the same time, its non-metallic shell will not cause any damage to the cable.

4.The anti-vibration section collides with the anti-vibration rod of the cable to weaken the breeze vibration on the cable.

5.The gripping section has grip elasticity, which can ensure that it will not be loose for a long time.

6.Convenient installation, without any tools, can be quickly and easily installed on site by hand, which can be completed by one person.

Specification required for different cable diameter ranges:

| No. | Item | Unit | Specification required for different cable diameter ranges (mm) | ||||

| 4.0 ~ 6.34 | 6.35~ 8.28 | 8.5 ~ 11.7 | 11.71 ~ 14.3 | 14.31 ~ 19.3 | |||

| 1.1 | Diameter | mm | 9.8-10.3 | 9.8-10.3 | 10.8-11.3 | 12.0-12.9 | 12.0-12.9 |

| 1.2 | Length | mm | 1250 | 1250 | 1300 | 1350 | 1650 |

| 1.3 | Gripping section length | mm | 300 | 300 | 350 | 350 | 350 |

Required number per span length:

| No | Item | Unit | Required number per span length (m) | ||||

| 100 | 200 | 300 | 400 | 500 | |||

| 1 | Spiral Vibration Damper | pc | 2 | 2 | 4 | 4 | 6 |

PRODUCT DRAWING:

Installation method:

1.The first one is installed at a distance >500mm from the end of the inner rods, and the second one is installed at a distance of 120mm from the end of the first one. This installation method can be called tandem installation.

2.The two pieces are stacked together and installed at a distance >500mm from the end of the guy grip. This installation method can be called parallel installation. (The two methods have basically the same vibration reduction effect).

Related Products

Related News

Submitted successfully

We will contact you as soon as possible