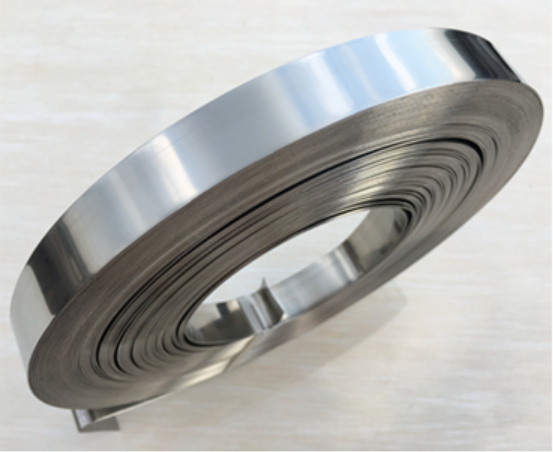

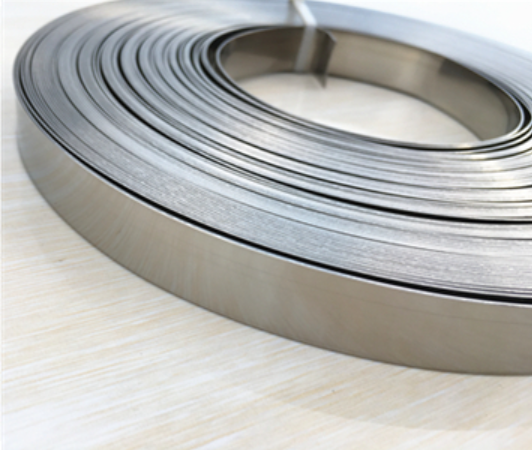

Metal Tape C201

All Well straps made of C201 stainless steel have a bright finish with fully rounded edges, excellent tensile properties, good resistance to oxidation and corrosive agents, which allows their use in environments where high resistance to corrosion is required, to fix pipes, cables, etc.

There are many types of cold-rolled steel strips and their applications are also very wide. In order to distinguish various chemical compositions and various purposes of strip steel, and to facilitate selection and use, it is necessary to understand the steel grade.

The stainless steel strip is made by further cold rolling. Compared with hot-rolled strip, it has higher dimensional accuracy, low surface roughness, good surface quality, smoothness, and higher strength.

FEATURES

-Tensile strength: 600 N / mm2

-Yield strength: 275 N / mm2

-Elongation (break): 40%

-Temperature: -60°C up to +60°C

-Standard: AISI 201

Measures:

-Width: 19mm

-Thickness: 0.7mm

-Length: 30 m. per roll

PRODUCT QUALITY CERTIFICATE

RAW MATERIAL PLANT: | HEJIAN YAXING STAINLESS STEEL PRODUCTS FACTORY | ||||

NO: HY-865247111 | Steel grade: A | ||||

NUMBER | MATERIAL | WIDTH | THICKNESS | LENGTH | PACKAGING |

1 | SS201 | 19.05mm | 0.76mm | 30m | cardboard |

YIELD STRENGTH | TENSILE STRENGTH | ELONGATION (BREAK) | |||

275N / mm2 | 600N / mm2 | 40% | |||

TECHNICAL COMPOSITION (%) | |||||||||

C | Si | Mn | P | S | Ni | Cr | Cu | N | AL |

0.09 | 0.45 | 6.5 | 0.038 | 0.004 | 1.26 | 13.57 | 0.8 | 0.15 | / |

Installation steps:

1.According to the actual use, cut a certain length of stainless steel cable tie, thread the buckle to one end of the tape, and reserve a length of about 5cm(Cutting length = the required length of the bundle+5cm+10cm).

2.Bend the reserved tape to preliminarily fix the stainless steel buckle.

3.When strapping, wear the other end of the stainless steel tape, and reserve a length of at least about 10cm for the strap tightening machine to pull into the tape.

4.clamping the tape with a tightening machine, and start to shake the rocker arm to slowly pull in the tape. Make sure that the tape is just tightened. Do not tighten the tape too much to avoid damage the tool.

5.When the tape is tightened, fold back the entire strap tightening machine and cut the tape by turning the blade handle.

6.Knock the two corners of the buckle flat with a hammer to block the final tape head to complete the binding process.

Wide range of applications Suitable for bundling all kinds of signs, traffic lights, cameras, pipelines, ships, bucket insulation projects, monitoring boxes, equipment electrical boxes, pole brackets, cable trays, etc.

304 material It is made of high-quality 304 stainless steel, with good toughness, fire-proof, waterproof and rust-proof, abrasion resistance, corrosion resistance, and durability.

Excellent quality The slitting is complete, polished, trimmed to remove burrs, smooth and not hurting hands, safe and reliable.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible