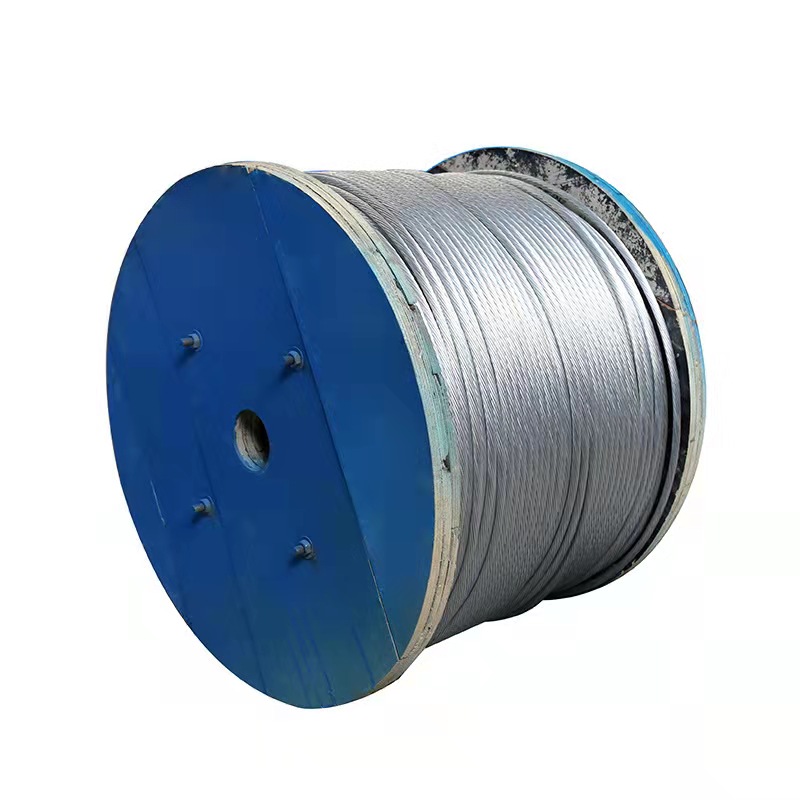

High Tension Galvanized Stay Earth Wire

Stranded wire is a steel product made up of multiple steel wires stranded, and a galvanized layer is added to the surface of the carbon steel. The galvanized steel strand is very flexible, and several galvanized steel wires are rotated together to form a beautiful steel product galvanized steel strand. The strength of the galvanized steel strand is very high and the stability is extremely good.

The galvanized steel strand is made of galvanized material and is composed of multiple steel wires. It has strong anti-rust, anti-rust ability, corrosion resistance, strong load-bearing, and good toughness. After multiple tensile tests, each steel wire rope has no breaks and no loose strands. The surface is smooth, burr-free, high tensile strength, and small bending radius. It is convenient and quick to bend and lay according to the construction environment and terrain.

Features:

1. Material: high strength carbon steel

2. Application: electric power, telecommunication, overhead line.

3. Finish: hot dip galvanized

Structure:

1×3 1×7 1×19

Process requirements for stranded wire:

1. The steel wire (including the central steel wire) of the steel strand should be the same diameter, the same strength, and the same zinc layer level.

2. The diameter and lay length of the steel strands should be uniform. They should not be loose after being cut.

3. The steel wires in the steel strand should be tightly twisted? There should be no staggering, breaking or bending.

4. The stranded wire should be straight, soft, and have low residual stress. It should not appear ∽ shape after unfolding.

5. 1x3 structural steel stranded wire and overhead ground wire are not allowed to be jointed. The inner steel wire joints of other types of steel stranded wire shall be connected by electric welding. The distance between any two joints shall not be less than 50m and the joints shall be treated with anti-corrosion treatment.

Related News

Submitted successfully

We will contact you as soon as possible